New Powder Metallurgy Technology that You Don't Want to Miss.

Jul. 24, 2023

New Powder Metallurgy Technology that You Don't Want to Miss.

Powder metallurgy is a process technology for preparing metal or using metal powder (or a mixture of metal powder and non-metal powder) as a raw material, forming and sintering to produce metal materials, composite materials and various types of products.

The powder metallurgy products industry in the common sense only refers to powder metallurgy products, including powder metallurgy parts (mostly), oil-bearing bearings and metal injection molding products. Today we will learn more about this process.

Process characteristics

1. The density of products is controllable, such as porous materials, high-density materials, etc.;

2. Fine grains, uniform microstructure, and no component segregation;

3. Near-shape forming, raw material utilization rate> 95%;

4. There is little and no cutting, and the cutting processing is only 40~50%;

5. The material components are controllable, which is conducive to the preparation of composite materials;

6. Preparation of insoluble metals, ceramic materials and nuclear materials.

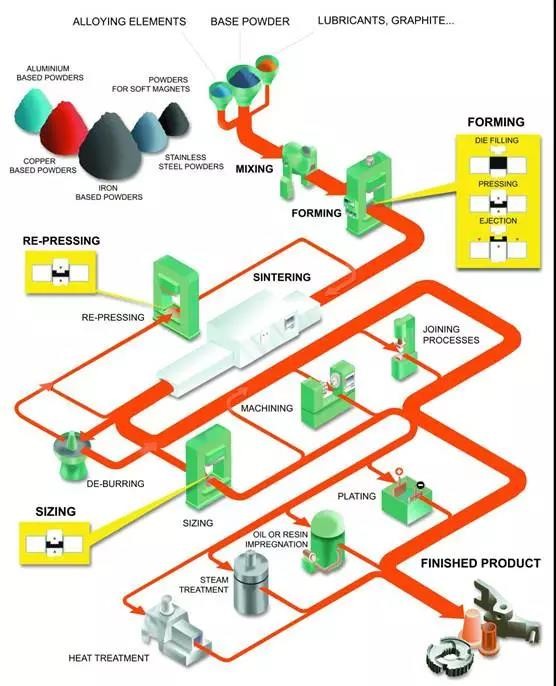

Basic technological process

1.Powder process

Powder making is the process of making powder from raw materials. The commonly used methods of powder making include oxide reduction and mechanical method

2.mixing powder material

Mixing is the process of mixing all kinds of required powders in a certain proportion and homogenizing them into billet powder.There are three types of separation: dry type, semi-dry type and wet type, respectively used for different requirements.

3.Forming

Forming is the process of forming a mixture powder with a certain shape, size and density by mixing evenly mixed materials into a pressing machine. Molding methods are basically divided into compression molding and non - compression molding. Die molding are widely used into the compression molding .

4.Sintering

Sintering is a key process in powder metallurgy process. The final physical and mechanical properties are obtained by sintering the formed pressed shape.

Sintering is divided into unit sintering and multi - sintering. In addition to ordinary sintering, there are also special sintering processes, such as loose sintering, melting and hot pressing.

5.Reprocessing

The treatment after sintering can be done in various ways according to the different requirements of the products. Such as finishing, oil immersion, machining, heat treatment and electroplating.In addition, in recent years, some new technologies such as rolling and forging have also been applied to the processing of powder metallurgy materials after sintering,and better results have been obtained.

Main application

Powder metallurgy products have a wide range of applications, from ordinary machinery manufacturing to precision instruments; From hardware tools to large machinery; From electronics to motor manufacturing;From civil industry to military industry;Powder metallurgy technology can be seen from general technology to cutting-edge high technology.

>>>>Typical Application-Automotive Industry

Powder metallurgy parts are widely used in automobiles

1. engine components

To improve fuel economy and control emissions, the working conditions of car engines have become more stringent. With powder metallurgy seats, valve guides, VCT and sprockets, it offers high strength, high wear resistance and excellent heat resistance.

2. Transmission components

Combining the nearly-formed synchronizer ring gear with dual friction materials and high-strength materials, the world's first clutch hub is made. In addition, through high-temperature sintering methods, high-strength parts such as handle shift gears and shift forks are manufactured.

The main components of powder metallurgy transmission in automobiles include: synchronizer hub, synchronizer ring, parking components, column shift components and control rods.

3. Shock absorber parts

In the shock absorbers of automobiles and motorcycles, piston rods and piston guide valves are important parts. Taking into account the stable damping force of the shock absorber, the use of powder metallurgy parts with high-precision sheet surface can reduce friction, ensure the stability of handling, and improve ride comfort.

>>>>Typical Application-Aerospace Industry

Among the powder metallurgy materials used in the aviation industry are special functional materials, such as friction materials, anti-friction materials, sealing materials, filter materials, etc., which are mainly used for aircraft and engine auxiliaries, instruments and airborne equipment. The other type is high-temperature and high-strength structural materials, which are mainly used for important structural parts of aircraft engine mainframes.

>>>>Typical Application-Household Appliances

Some materials and parts of household appliances can only be made by powder metallurgy, such as the porous self-lubricating bearings in refrigerators, compressors, washing machines, electric fans, etc.

Some materials and parts for home appliances, such as the complex shaped gears and magnets used in home air conditioning fans and vacuum cleaners, are made of powder metallurgy to produce better quality and lower prices.

>>>>Typical Application-Power Tools

Thanks for reading!

If you have any idea about this article, please contact me feel free. Thanks for watching, and have a nice day!